Liquid fuels have in their composition a part of free carbon and hydrogen molecules to agglomerate after production, besides retaining water by condensation.

The combination of agglomeration and sedimentation processes of asphaltenes, gums, paraffin, other sediments and biomass produced by bacteria, fungi and algae leads to the deposition of “sludge” at the bottom of storage tanks;

The sludge thus consists of solid and semi-solid impurities of different types, which accumulate along the mechanical systems, from storage to filters, affecting supply, reducing useful storage capacity, causing corrosion and clogging and damage to plants and equipment.

In storage, sludge removal is a costly process that requires lengthy operational downtime, as well as difficulties in disposing of the resulting materials and the possibility of environmental consequences.

However, fuels can be stabilized after distillation by using additives to disperse the larger agglomerations and increase the smaller particles, bringing the products closer to optimum specifications.

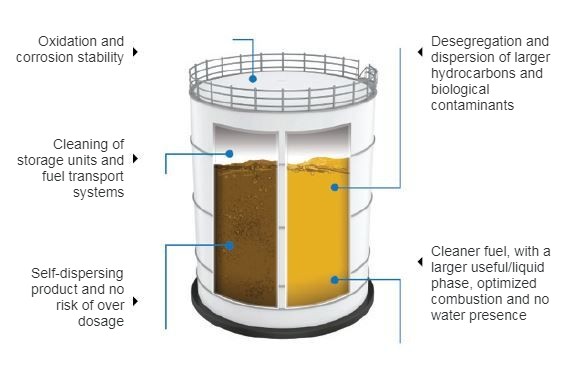

The physical effect ecoStorm promotes the separation of the molecules adhering to the substrate of the storage tanks (walls and bottoms), subsequently disintegrating and dispersing the existing molecules.

The surfactant properties of the product create a protective film around the aromatic hydrocarbon molecules, promoting the reduction of the surface/interfacial tension, preventing agglomeration and dissolving the existing sludge.

Advantages of the regular use of ecoStorm in storage:

Less Sludge

Less Maintenance Costs

Less Waste

More Combustible Volume

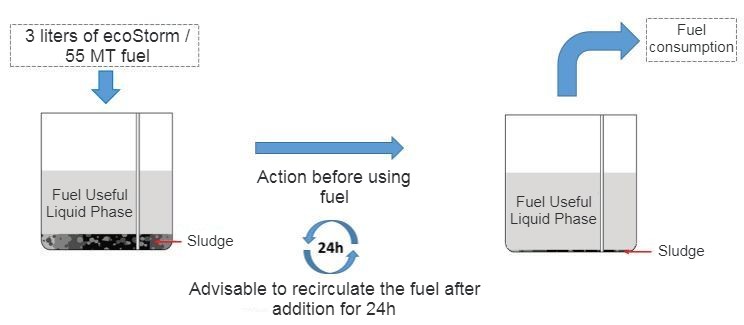

Initial approach to a reservoir with a severe case of sludge

© 2021 Copyright Sustainable Level, SA