Experience in fuel treatments to improve efficiency, performance, and sustainability of fuels around the world.

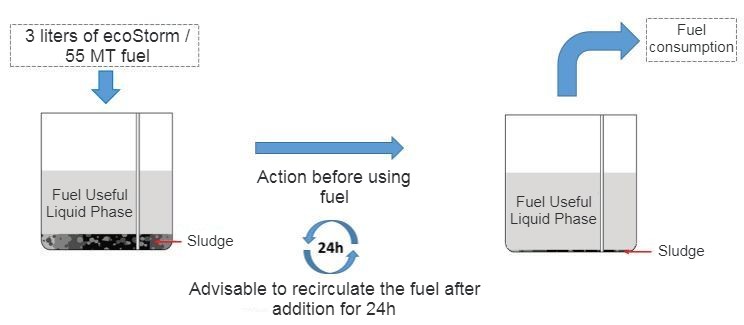

Made from plant extracts and extremely concentrated (1 liter will treat 55 metric tons/cubic meter of fuel), ecoStorm 4-in-1 fuel conditioner is the responsible choice in terms of economy, efficiency and the environment.

Being 100% plant-organic, this state-of-the-art fuel conditioner contains no ash or metals, setting a benchmark for sustainability in fuel treatment solutions.

Not being classified as a hazardous material, it is safe to handle and has no transport restrictions, as well as no risk of over dosage.

The ecoStorm 4-in-1 conditioner enables the fuel used in all internal combustion engines to have better combustion, power and efficiency, in a more sustainable and organic way.

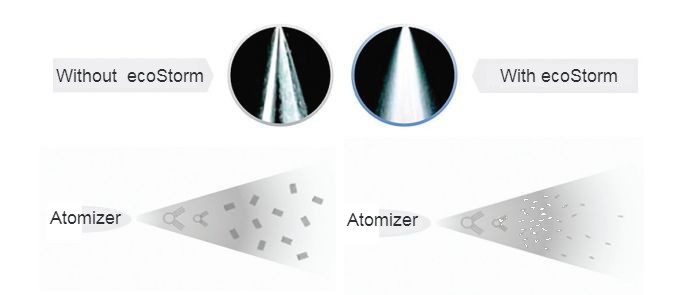

The ecoStorm products have a physical disintegrating action, fully preserving the chemical specifications of the fuel.

Regular use means much improved performance and efficiency of all internal combustion engines, as well as mitigating and preventing preventive maintenance actions, regardless of their size and in all areas such as transport, shipping, construction, etc.

In addition to improving combustion, and thereby improving efficiency, the ecoStorm fuel treatment system optimizes operations to be performed at higher engine performance levels and regimes and for longer periods by minimizing the risks of mechanical exhaust.

ecoStorm products include a consultative service by a highly specialized technical team to tailor our solutions to the specific challenges of your operating environment.

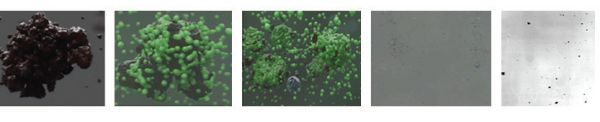

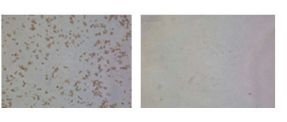

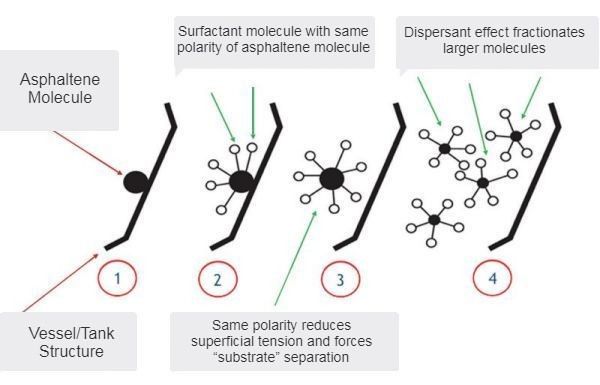

ecoStorm has a visible physical action on the dispersion of alphaltenes present in fuels

Example of the dispersing efficiency of ecoStorm on paper filters, compared to a specimen with another additive and a test without additive.

ecoStorm has a physical disintegrating action, fully preserving the chemical specifications of the fuel

Sustainability is the possibility of conservation of a process or system.

The concept of sustainability addresses how one should act towards nature and the environment, and it should apply from a community to the entire planet.

“Development that meets present needs without compromising the ability of future generations to meet their own needs”

At ecoStorm, we take this matter very seriously. In order to take a step towards true sustainability, we must measure and compare different operational scenarios and select the one with the most sustainable outcome. To do this, we must consider and work with the 3 pillars of sustainability, namely Efficiency, Economy and Environment.

By taking into account different elements to have an effect on carbon emissions and other substances in the environment, we can get a benchmark to compare different scenarios.

Our goal is to find a solution that minimizes carbon emissions in an internal combustion engine operation by working on the parameters related to fuel only.

A number of options need to be addressed in order to select the most sustainable solution.

In the end, this is the first step towards sustainability and the right choice for building a responsible corporate image and making a real contribution to the sustainable reduction of carbon emissions and climate change caused by the operation of internal combustion engines.

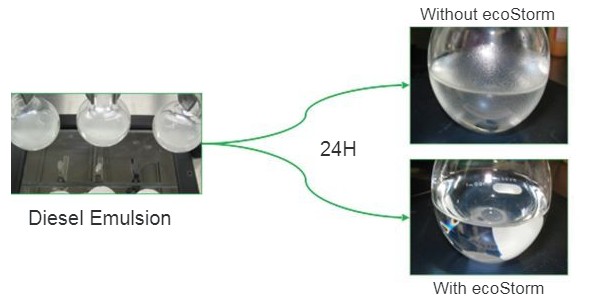

Liquid fuels have in their composition a part of free carbon and hydrogen molecules to agglomerate after production, besides retaining water by condensation.

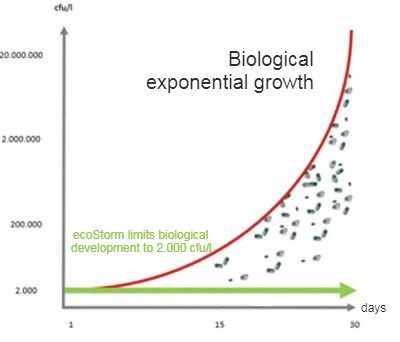

The combination of agglomeration and sedimentation processes of asphaltenes, gums, paraffin, other sediments and biomass produced by bacteria, fungi and algae leads to the deposition of “sludge” at the bottom of storage tanks;

The sludge thus consists of solid and semi-solid impurities of different types, which accumulate along the mechanical systems, from storage to filters, affecting supply, reducing useful storage capacity, causing corrosion and clogging and damage to plants and equipment.

In storage, sludge removal is a costly process that requires lengthy operational downtime, as well as difficulties in disposing of the resulting materials and the possibility of environmental consequences.

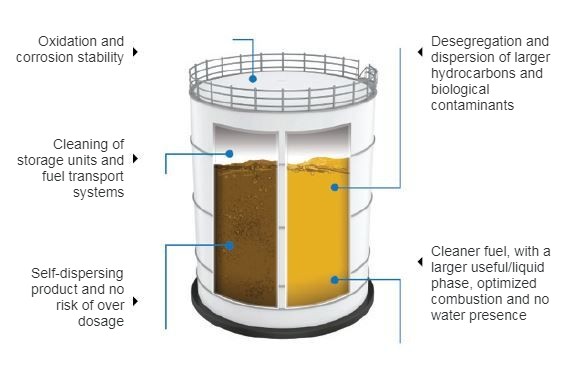

However, fuels can be stabilized after distillation by using additives to disperse the larger agglomerations and increase the smaller particles, bringing the products closer to optimum specifications.

The physical effect ecoStorm promotes the separation of the molecules adhering to the substrate of the storage tanks (walls and bottoms), subsequently disintegrating and dispersing the existing molecules.

The surfactant properties of the product create a protective film around the aromatic hydrocarbon molecules, promoting the reduction of the surface/interfacial tension, preventing agglomeration and dissolving the existing sludge.

Advantages of the regular use of ecoStorm in storage:

Less Sludge

Less Maintenance Costs

Less Waste

More Combustible Volume

Initial approach to a reservoir with a severe case of sludge

© 2021 Copyright Sustainable Level, SA